PET FOAM

Heat deflection temperature:80℃-120℃

✓High-Temperature Resistance: Stable up to 80℃-120℃, with excellent dimensional stability under thermal stress.

✓Outstanding Strength-to-Weight Ratio: Exceptional stiffness and compressive strength, ideal for load-bearing and sandwich core applications.

✓Chemical & Moisture Resistance: Highly resistant to water, solvents, and UV radiation, ensuring long-term durability in harsh environments.

✓Customizable Solutions: Advanced R&D capabilities to modify density, thickness, and surface treatments for specialized needs.

✓Fast Turnaround: Quick prototyping and reliable delivery, with samples available in 5–7 days and bulk orders in 10–15 days.

Product Details

1.PET foam is a lightweight yet high-strength structural foam produced through the expansion and thermoforming of polyethylene terephthalate (PET), a thermoplastic polymer known for its excellent mechanical and thermal properties.

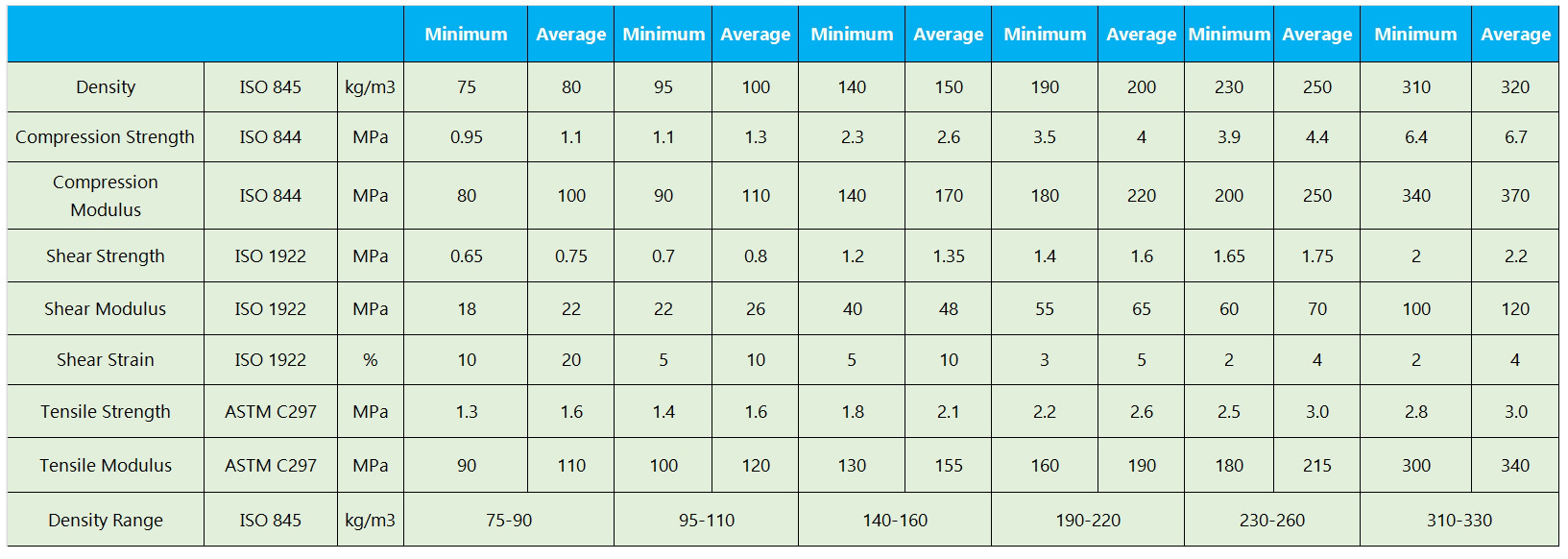

2.One of the most notable advantages of PET foam is its low density, typically ranging from 75 to 320 kg/m³, making it an ideal core material for weight-sensitive applications.

3.PET foam demonstrates outstanding thermal resistance, with a continuous service temperature range of 80℃-120℃, ensuring stability under thermal stress.

4.Despite its lightweight nature, PET foam exhibits high compressive strength, stiffness, and impact resistance, making it suitable for load-bearing structures and sandwich panel cores.

5.PET foam is widely used in industries such as wind energy, marine, automotive, construction, and transportation, thanks to its durability and superior performance-to-weight ratio.

Parameters

Application

PET foam is widely used across industries due to its lightweight, high strength, and recyclability. Key applications include wind turbine blades and solar panels in renewable energy; automotive parts, marine cores, and aircraft interiors in transportation; building facades and flooring in construction; protective and food packaging in packaging; as well as sports equipment and industrial displays.

|  |  |  |

PET Foam Packaging

1.Wrap PET foam with bubble wrap or foam sheets to create a protective cushioning layer against impacts and scratches. Pay special attention to covering all surfaces, particularly the edges and corners which are most vulnerable to damage.

2.Pack securely in wooden cases or sturdy cartons to prevent compression during transit. Store in a cool, dry environment away from direct sunlight and moisture to maintain material integrity.

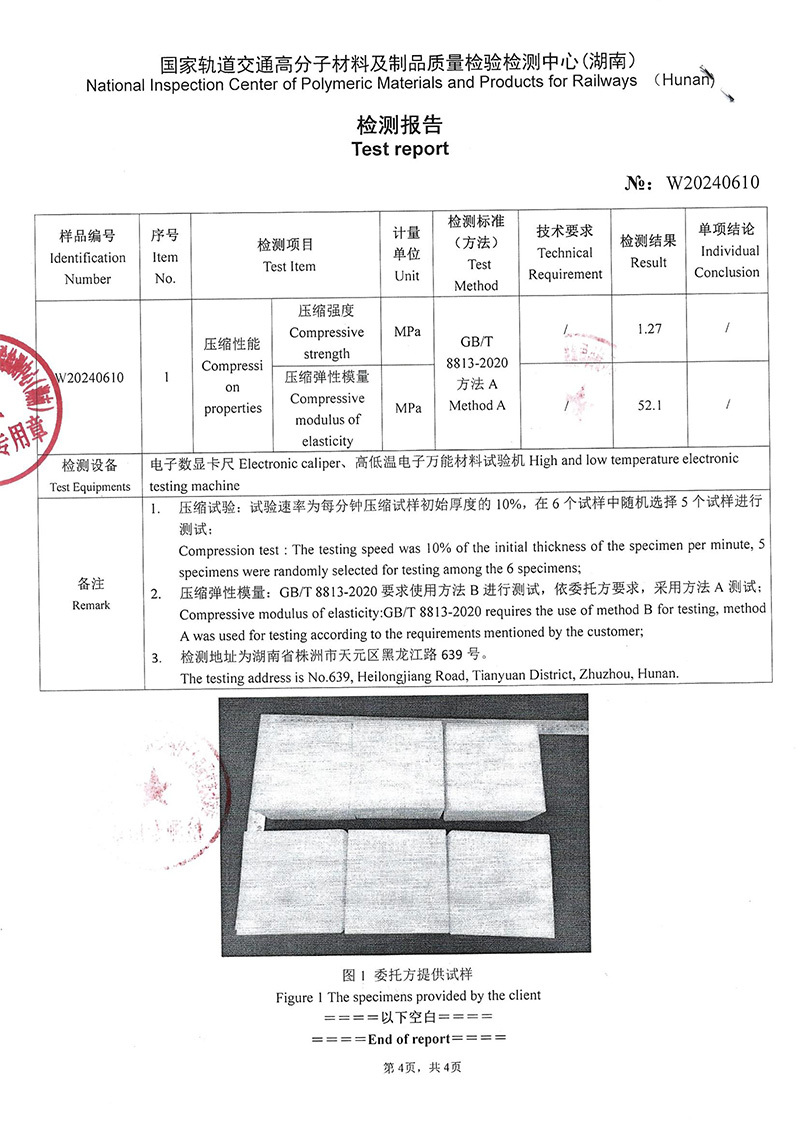

Qualification Certificate

Related Products