Advancements in PET Foam Technology: From Wind Turbine Blades to Sustainable Packaging

The global demand for lightweight, high-performance materials has propelled polyethylene terephthalate (PET) foam into the spotlight across industries. Originally recognized for its role in beverage bottles, PET’s transformation into a structural foam through advanced extrusion and chemical modification processes has unlocked applications in renewable energy, aerospace, and sustainable packaging. This article explores how PET foam’s unique properties—thermal stability, recyclability, and shear resistance—are driving innovation in key sectors.

1. Wind Turbine Blades: A Renewable Energy Game-Changer

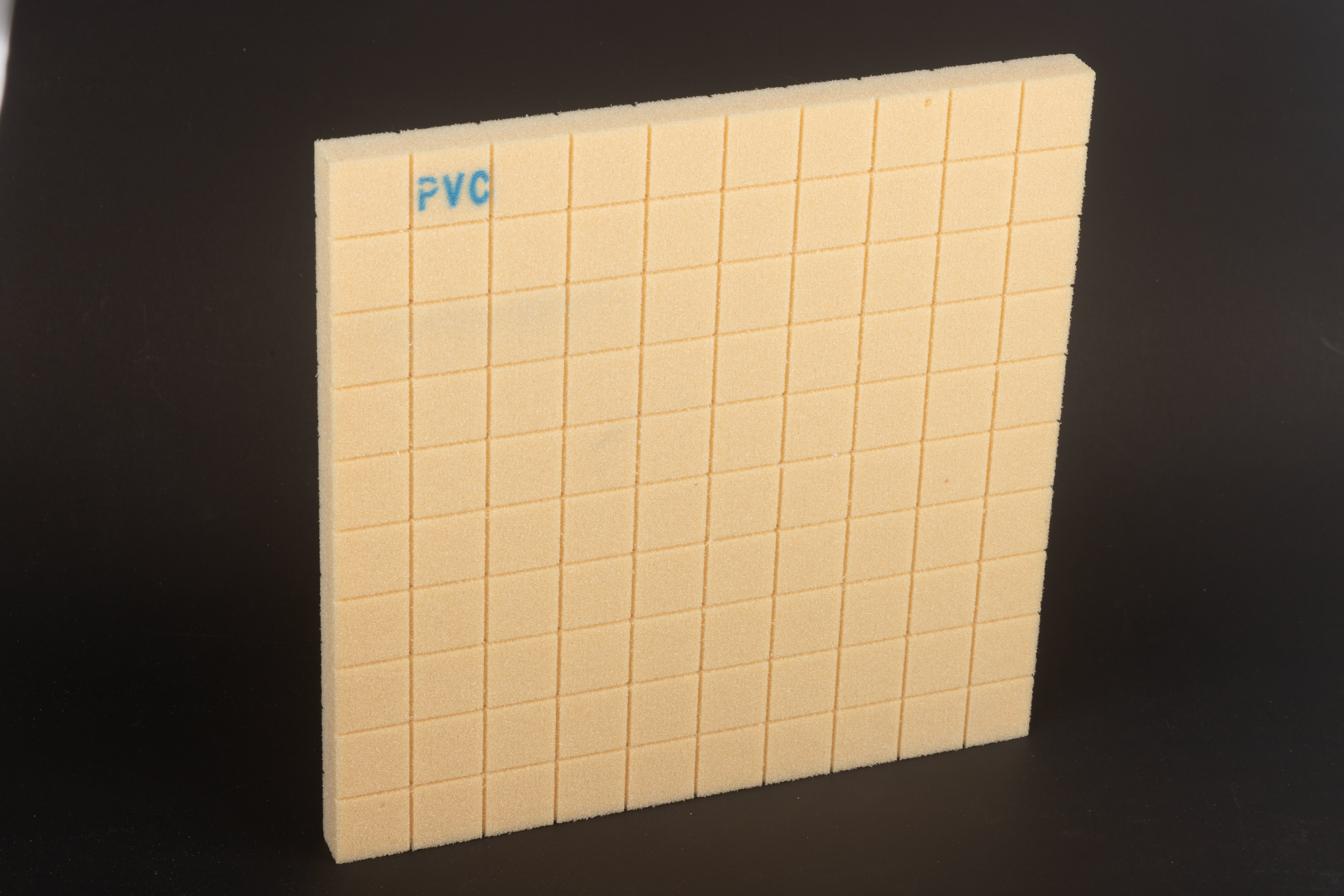

The wind energy sector accounts for over 40% of global PET foam consumption, primarily due to its role as a core material in turbine blades. Unlike traditional PVC or balsa wood, PET foam offers a superior balance of stiffness and fatigue resistance.

China’s dominance in PET foam production—with a 2023 capacity exceeding 1 million cubic meters—has reduced costs by 30% since 2018, accelerating adoption in domestic and international markets.

2. Sustainable Packaging: Closing the Loop on Plastic Waste

PET foam’s recyclability addresses one of the packaging industry’s most pressing challenges: plastic pollution. Unlike expanded polystyrene (EPS), which fragments into microplastics, PET foam can be reprocessed into new products without significant degradation.

Innovations in chemical recycling further enhance PET foam’s sustainability.

3. Aerospace and Automotive: Lightweighting for Fuel Efficiency

The aerospace industry is leveraging PET foam’s low density (as low as 60 kg/m³) to reduce aircraft weight. Airbus incorporated PET foam composites into the A350’s cabin panels, cutting weight by 15% versus traditional aluminum. Similarly, automotive manufacturers are using PET foam for seat cushions and interior trim, achieving a 20% reduction in vehicle mass.

As research focuses on enhancing fire resistance and reducing resin absorption rates, PET foam is poised to disrupt industries beyond its current applications. The material’s versatility—from renewable energy infrastructure to everyday packaging—underscores its potential to drive a more sustainable, circular economy.

PET FOAM

Latest News