Hunan Xintan New Materials Technology Co., Ltd.: The Path to R&D and Industrialization of High-Performance PMI Foam

Hunan Xintan New Materials Technology Co., Ltd. is a company located in Changsha, Hunan province, that specializes in the industrialization of polymethacrylimide (PMI) structural foam materials. The company aims to achieve complete domestic production of high-performance PMI foam. Through its strong innovation capabilities, the company has successfully developed high-performance PMI foam, filling a gap in the domestic market.

Hunan Xintan New Materials Technology Co., Ltd. has accumulated extensive practical experience in engineering conversion and industrialization. The company has brought together a highly innovative R&D team dedicated to the research, development, and industrialization of PMI foam. They are committed to providing customers with excellent products and attentive service. Through collaborative innovation, they aim to drive the R&D and industrialization of advanced polymer materials. By combining their technological expertise and practical experience, the team is dedicated to offering customers high-performance polymer new materials with exceptional service. This initiative will further promote the development of the polymer materials industry and support industrial upgrading.

Product Overview: XT foam Structural Foam

XT foam structural foam is a 100% closed-cell, rigid polymethacrylimide (PMI) foam that offers a multitude of exceptional properties. It features high specific strength and high specific modulus, along with excellent heat resistance, compressive strength, corrosion resistance, and good dielectric properties. This foam can be co-cured with medium to high-temperature resins such as epoxy and bismaleimide, making it suitable for a wide range of applications. XT foam is used in aerospace, rail transit, shipbuilding, new energy vehicles, wind power generation, sports equipment, radar antennas, and medical beds.

Key Characteristics of XT foam

XT foam structural foam, with its unique 100% closed-cell and rigid PMI foam structure, exhibits several remarkable characteristics. It offers not only high specific strength and modulus but also excellent performance in heat resistance, compressive strength, and corrosion resistance. Its good dielectric properties make it ideal for electronic applications. Furthermore, XT foam can be co-cured with medium to high-temperature resins like epoxy and bismaleimide, significantly expanding its application scope. It plays an indispensable role in heavy industries like aerospace, rail transit, shipbuilding, and new energy vehicles, as well as emerging sectors such as wind power generation and sports equipment, and specialized fields like radar antennas and medical beds.

Lightweight and High-Strength Foam Material:

Compared to rigid foams like cross-linked PVC, rigid PU, PET, and PEI, XT foam structural foam exhibits superior strength and modulus at the same density. To meet the same strength requirements, XT foam is 20%-50% lighter than cross-linked PVC foam and 40%-80% lighter than rigid PU foam, highlighting its lightweight and high-strength properties.

High-Temperature Resistant Rigid Structural Foam:

XT foam structural foam shows excellent anti-creep performance in high-temperature environments, easily handling demanding process conditions of 180°C/0.7MPa. This foam is suitable for autoclave processes and can be used with high-performance resins such as medium- to high-temperature epoxy and bismaleimide, significantly improving product performance while reducing the manufacturing cost of composite materials.

100% Closed-Cell Structural Foam:

XT foam is produced through a refined solid-plate foaming process, resulting in a 100% closed-cell structure. This unique design effectively reduces resin absorption during the composite molding process, contributing to improved product performance and reduced manufacturing costs.

Air-like Wave-Permeable Foam:

XT foam structural foam has an extremely low dielectric constant in the broadband range, between 1.05 and 1.13, and a low aluminum equivalent, making it an ideal foam core material for radar radomes and medical beds.

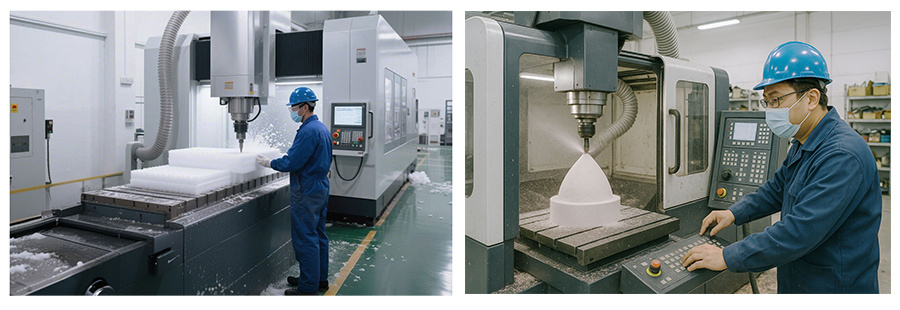

Easy to Process like Wood:

XT foam structural foam can be processed using various methods, including sawing, planing, milling, drilling, grinding, and CNC. Its processing is very similar to that of wood, making it simple and efficient.

Highly Formable and Easy to Shape:

When heated, XT foam structural foam shows excellent plasticity, allowing it to be easily shaped into various complex geometries to meet different application needs.

Applications of XT foam

Aerospace

In the aerospace sector, XT foam structural foam provides revolutionary value with its excellent formability and shaping capabilities. Its unique characteristic of being shaped after heating allows it to easily conform to complex geometries, meeting the high-precision demands of the industry. The outstanding high-temperature creep resistance of XT foam enables the co-curing of core and skin, shortening the manufacturing cycle. Compared to traditional honeycomb structures, its product surface is smoother, enhancing overall aesthetics and performance. Its high specific strength and modulus properties maximize weight reduction, leading to fuel savings. These advantages make XT foam indispensable in aerospace.

Rail Transit

With the rapid development of urban rail transit, the demand for lightweight and high-performance materials is increasing. XT foam structural foam, with its excellent physical properties and process characteristics, provides innovative solutions for the rail transit sector, helping to achieve lightweighting goals. XT foam composite materials offer significant advantages in rail transit. Their lightweight nature effectively reduces vehicle weight, improving acceleration and lowering energy consumption. Furthermore, the material produces less smoke and is non-toxic when burned, providing a strong safety guarantee for passengers.

Wind Power Generation

XT foam composite materials' high specific modulus allows for a 20% weight reduction in wind turbine units, which is crucial for designing longer blades. Its excellent thermal performance enables higher curing temperatures, further shortening production cycles and reducing costs. These advantages make XT foam composite materials particularly well-suited for wind power generation.

Medical

XT foam composite materials, with their extremely low aluminum equivalent, enable medical beds using it as a core to obtain uniform and clear images with minimal radiation doses. This is vital for medical diagnostics, improving accuracy and ensuring patient safety.

Radar Antennas

XT foam's dielectric constant is close to that of air, ranging from 1.05 to 1.13. This low aluminum equivalent characteristic allows radar antennas to achieve efficient and stable signal reception and transmission with lower power and smaller sizes. This technological breakthrough advances radar technology and brings revolutionary changes to military and aviation fields. To meet the same strength requirements, a lower-density foam material can be used, further improving wave penetration.

Drones

XT foam sandwich structures are used in drones for their significant weight reduction, effectively extending flight range.

Sports Equipment

PMI foam,structural foam

Latest News