PMI Foam vs. PVC: Why PMI Emerges as the Superior Core Material for Advanced Composites

Introduction

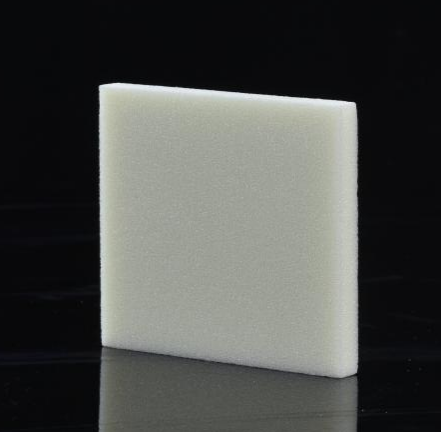

In the world of composite sandwich structures, core materials like PMI (Polymethacrylimide) foam and PVC (Polyvinyl Chloride) foam play pivotal roles. While PVC foam has long been valued for its cost-effectiveness and versatility, PMI foam stands out as a superior choice for high-performance applications. This article explores the key advantages of PMI foam over PVC, highlighting why industries like aerospace, wind energy, and automotive are increasingly adopting PMI.

1. Superior Thermal Stability and High-Temperature Performance

PMI foam excels in high-temperature environments, maintaining structural integrity under extreme conditions. It can withstand temperatures up to 190°C and pressures of 0.7 MPa during autoclave curing, making it compatible with epoxy or BMI resins . In contrast, PVC foam has a lower thermal stability, with a maximum service temperature of 120°C . When exposed to medium-temperature curing processes (e.g., 70–90°C), PVC tends to shrink and release gases, leading to defects like panel delamination . PMI’s resilience ensures dimensional stability, critical for aerospace and precision engineering.

2. Exceptional Mechanical Properties

PMI foam boasts the highest specific strength and stiffness among polymer foams . Its closed-cell structure provides excellent compression creep resistance, enabling it to bear heavy loads without deformation. PVC foam, though mechanically robust, lacks PMI’s stiffness and fatigue resistance . For instance, PMI-based composites achieve over 30% weight reduction while improving mechanical performance by 10% compared to metal parts . This makes PMI ideal for lightweight yet strong components like aircraft interiors and wind turbine blades.

3. Compatibility with Advanced Manufacturing Processes

PMI foam is optimized for high-pressure processes like autoclave curing and resin transfer molding (RTM). Its low resin absorption rate prevents weight gain and ensures uniform composite quality . Conversely, PVC foam releases gases during RTM, risking porosity in panels . PMI’s machinability also allows for complex 3D shapes, surpassing PVC’s limitations in designing curved or intricate parts.

4. Enhanced Safety and Environmental Profile

PMI foam meets stringent FST (fire, smoke, toxicity) standards, emitting low smoke density and no toxic halogens when burned . PVC, however, releases hydrogen chloride (HCl) gas upon combustion, posing health and environmental risks . Additionally, PMI’s halogen-free composition aligns with green manufacturing trends, while PVC’s recycling remains challenging due to chemical additives.

5. Future-Ready Applications

While PVC dominates cost-sensitive sectors like marine and construction, PMI is the material of choice for cutting-edge industries. It is already used in NASA’s Delta rocket fairings, high-speed train fronts, and Vestas’ wind turbine blades . As demand for lightweight, sustainable materials grows, PMI’s role in electric vehicles and renewable energy will expand.

Conclusion

PMI foam’s unmatched thermal stability, mechanical strength, and processability make it a game-changer for high-performance composites. Though PVC remains relevant for budget-friendly projects, PMI is the definitive solution for innovation-driven industries. By choosing PMI, manufacturers ensure superior product longevity, safety, and efficiency.

PMI foam,Polymethacrylimide

Latest News