XT-Y75X High strength PMI Foam Core

Heat deflection temperature:180℃

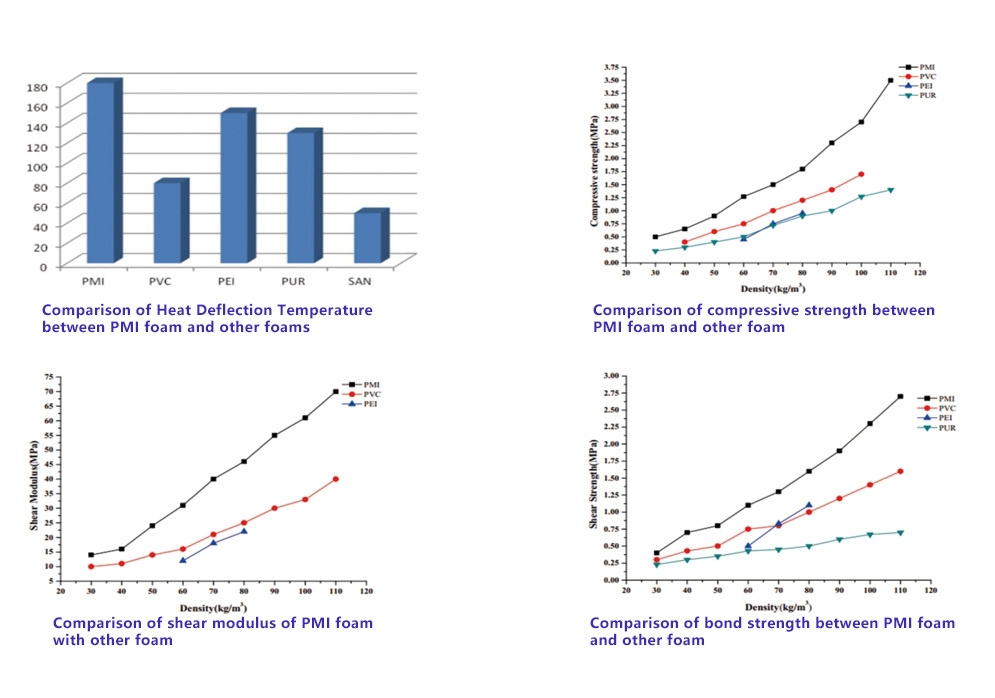

√ Thermal Resistance: Withstands up to 180°C without deformation, non-combustible, and self-extinguishing.

√ Mechanical Strength: High strength despite low density, with superior surface quality.

√ Independent R&D capability: Complete experimental and R&D department, according to customer needs and rapid response.

√ Rapid response: Provide a complete solution within 72 hours of receipt of the request.

√ Fast delivery: Ships within 7 days of receipt of order.

Product Details

1.PMI foam is a high-performance polymeric structural foam produced by foaming and crosslinking raw materials such as MAA (methacrylic acid), MAN (maleic anhydride), and AN (acrylonitrile) at elevated temperatures.

2.One of the standout features of PMI foam is its incredibly low density. The foam can be produced with densities as low as 30 kg/m³

3.PMI foam exhibits excellent thermal stability, capable of withstanding temperatures up to 180°C without deformation. Additionally, it is non-combustible .

4.Despite its low density, PMI foam offers exceptional mechanical strength.

5.PMI foam is widely used in aerospace, automotive, construction, and other industries

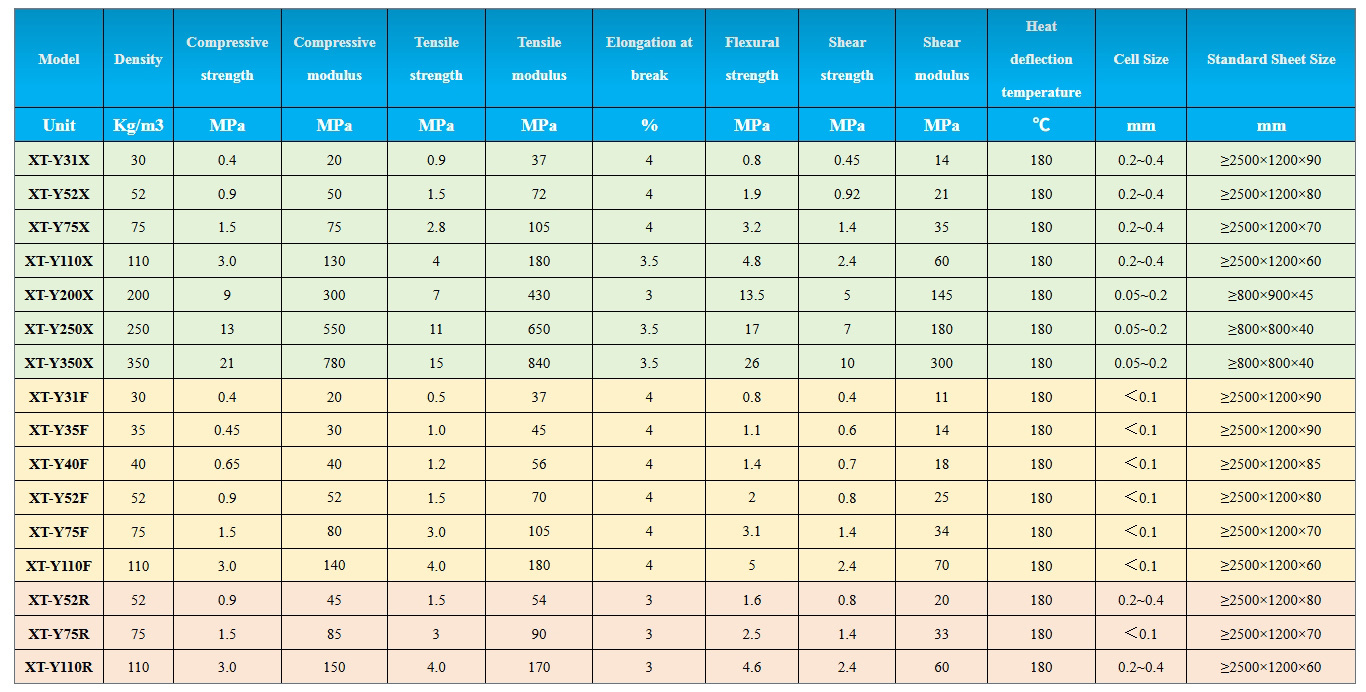

Parameters

Application

PMI foam is a versatile material that stands out due to its lightweight properties, high thermal resistance, and exceptional mechanical strength. These characteristics make it suitable for a wide range of applications across various industries. Below, we explore some of the key applications of PMI foam and how its unique properties benefit these sectors.

|

|

|

|

| Aerospace Industry | Automotive Industry | Radome& Antenna | Medical Devices |

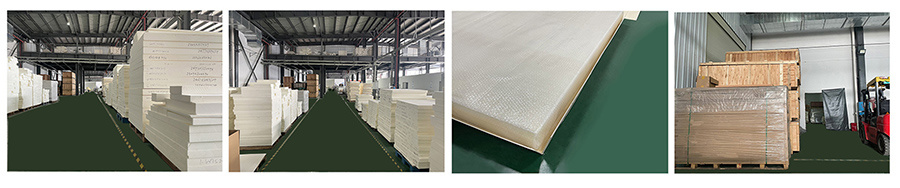

Production workshop

Packaging

- Use bubble wrap or foam sheets to wrap the PMI foam. This provides a cushioning layer to protect against impact and abrasions. Ensure that the entire surface area is covered, especially the edges and corners, which are more susceptible to damage.

- Packed by wood case or carton. Keep it in dry place.

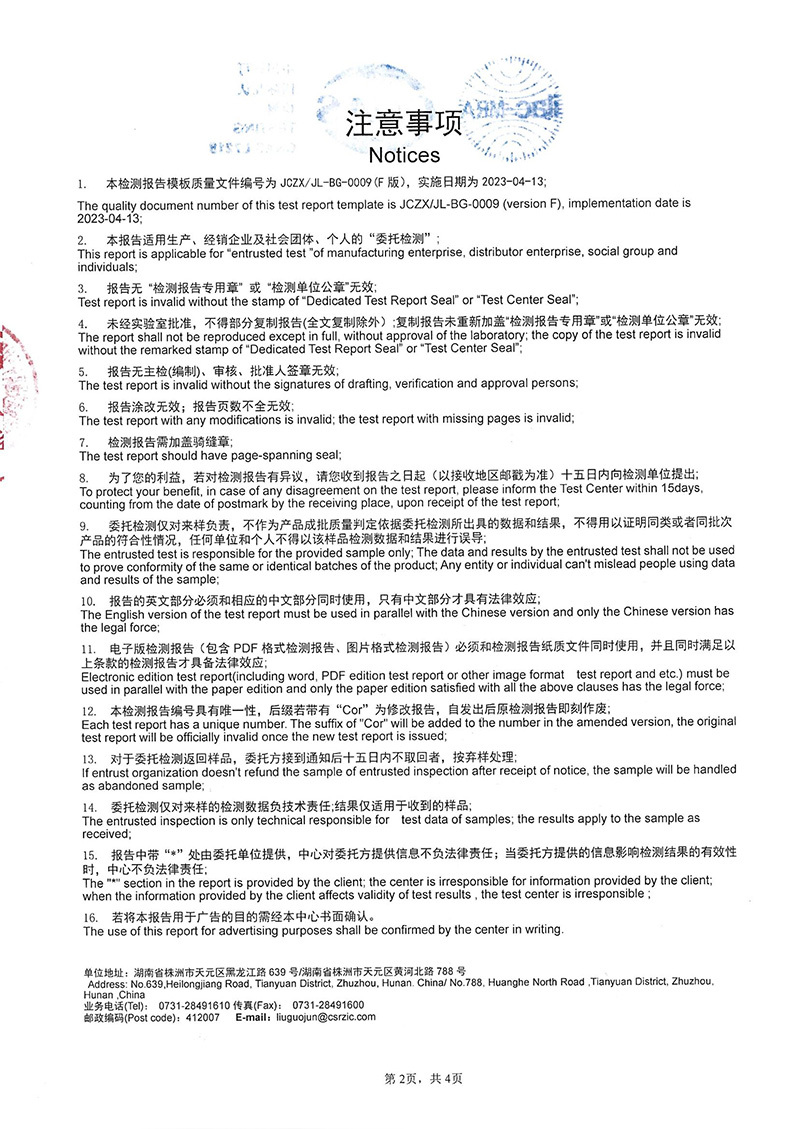

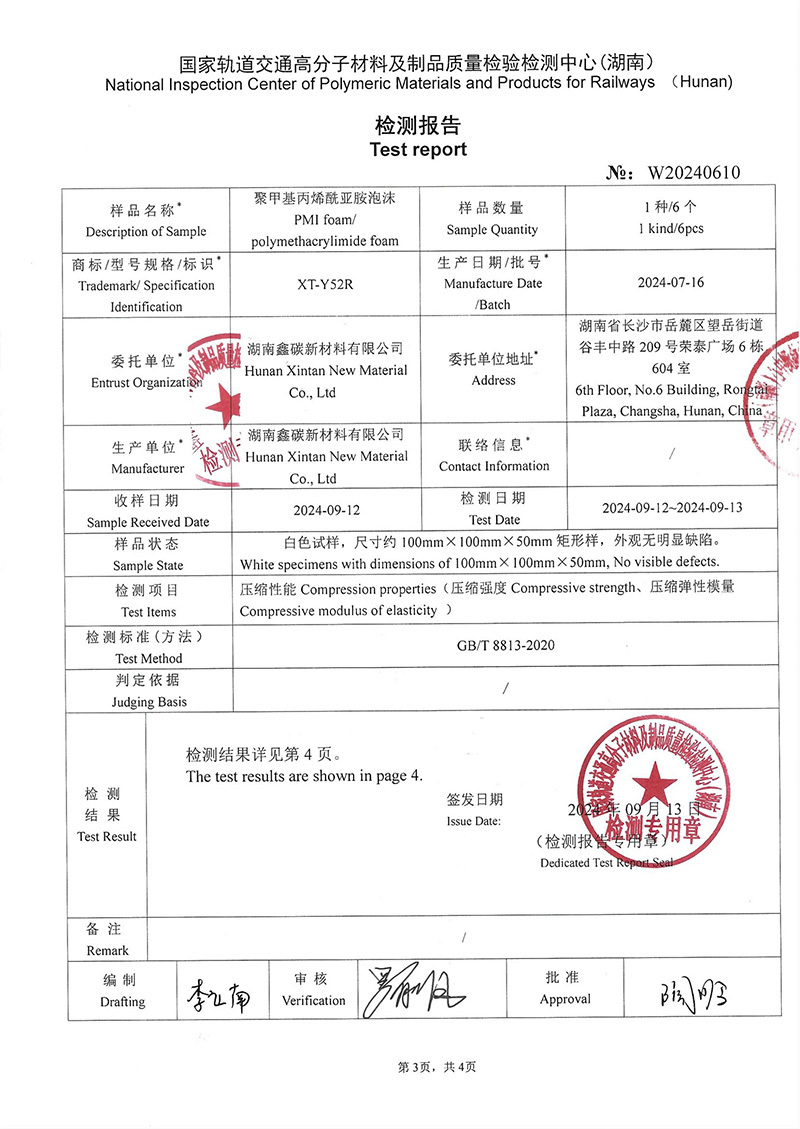

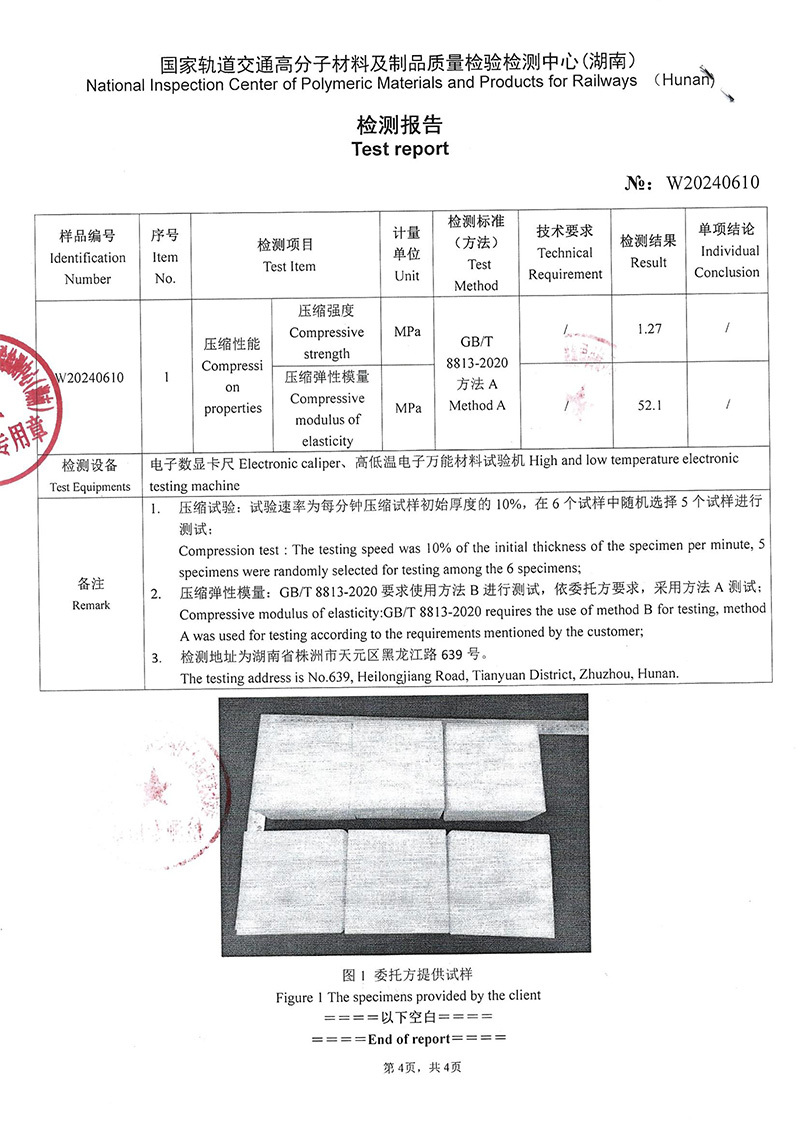

Qualification Certificate

Related Products

previous page

next page