The Future of PMI Foam: Emerging Trends and Market Outlook

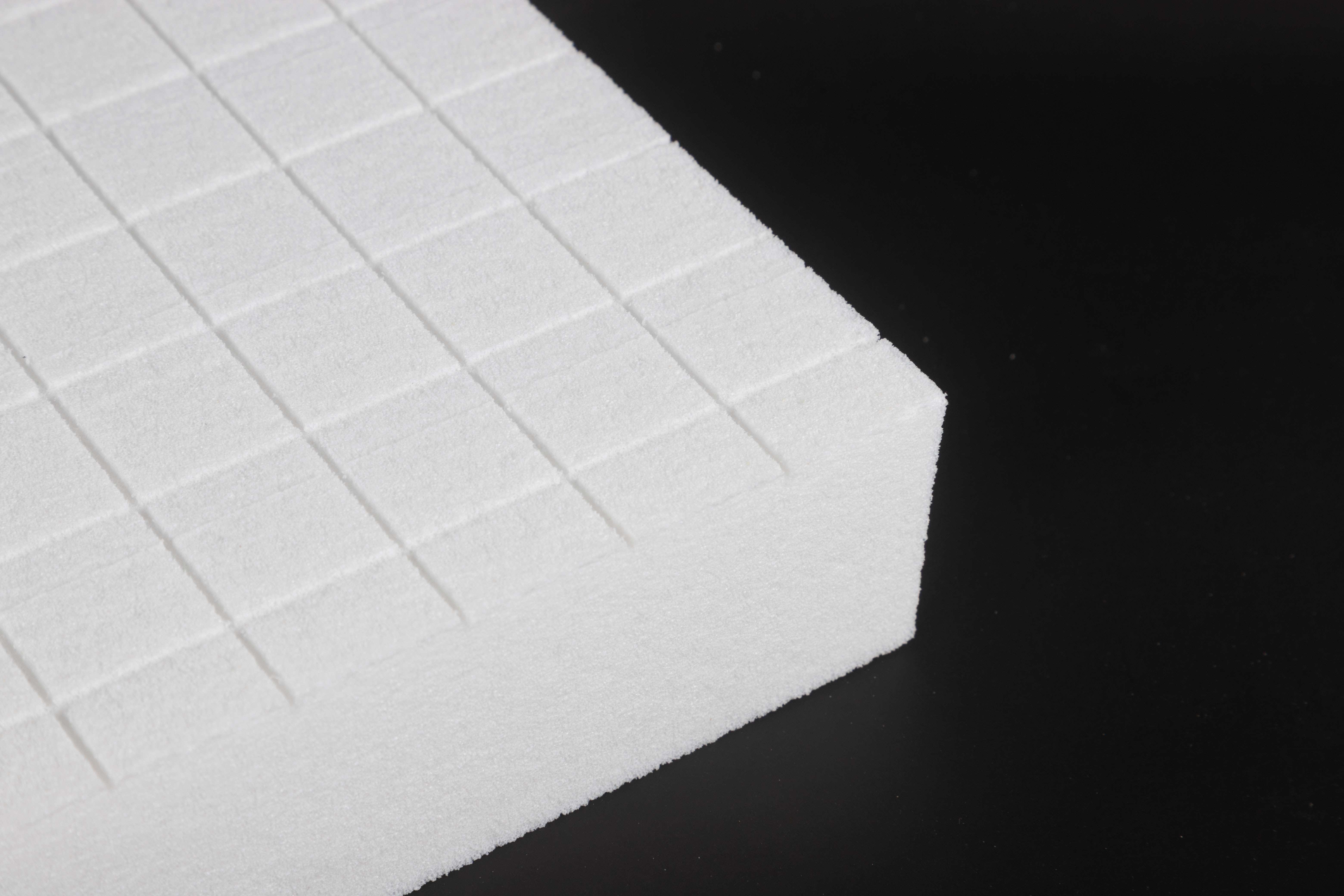

Polymer matrix foam, specifically polymethacrylimide (PMI) foam, has become a cornerstone material in high-performance industries such as aerospace, wind energy, automotive, and marine. Known for its excellent mechanical properties, lightweight structure, and thermal resistance, PMI foam is increasingly being adopted across sectors that demand durability without added weight.

As we move further into the 2020s, the market for PMI foam is poised for significant growth driven by technological advancements, rising demand for sustainable materials, and expanding applications in emerging fields like electric vehicles and advanced composites.

1. Rising Demand from Aerospace Industry

The aerospace sector remains one of the largest consumers of PMI foam due to its superior strength-to-weight ratio and compatibility with carbon fiber-reinforced plastics (CFRP). In modern aircraft manufacturing, PMI foam is used extensively in wing structures, fuselage panels, and control surfaces. With major players like Airbus and Boeing investing heavily in next-generation aircraft designs that emphasize fuel efficiency and reduced emissions, the need for lightweight, high-strength core materials like PMI foam is expected to surge.

Moreover, the rise of commercial space travel and unmanned aerial vehicles (UAVs) is opening new avenues for PMI foam applications, where structural integrity and minimal weight are critical factors.

2. Growth in Wind Energy Sector

The renewable energy industry, particularly wind turbine manufacturing, is another key driver behind the growing PMI foam market. As global governments push for greener energy solutions, the size and efficiency of wind turbines have increased dramatically. Larger rotor blades require lightweight yet durable core materials to maintain structural stability and aerodynamic performance.

Compared to traditional balsa wood or PVC foams, PMI foam offers better fatigue resistance, higher temperature tolerance, and improved bonding characteristics with composite skins. These advantages make it an ideal choice for next-generation wind blades, especially in offshore wind farms where environmental conditions are more extreme.

3. Expansion into Automotive and Electric Vehicles

With the rapid evolution of the electric vehicle (EV) industry, manufacturers are constantly seeking ways to reduce vehicle weight to improve battery efficiency and extend driving range. PMI foam’s lightness and structural rigidity make it a promising candidate for use in EV body panels, battery enclosures, and interior components.

Additionally, as automakers explore the use of advanced sandwich composites for structural parts, PMI foam is gaining traction as a core material that enhances crash performance while reducing overall mass. This trend is likely to accelerate as stricter emission regulations and consumer demand for longer-range EVs continue to shape the automotive landscape.

4. Technological Advancements and Customization

Recent innovations in foam processing technologies have enabled manufacturers to produce PMI foam with tailored properties, including varying densities, cell structures, and fire-resistant formulations. These developments allow engineers to optimize material performance for specific applications, thereby increasing adoption across niche markets.

For instance, flame-retardant PMI foams are now being developed for use in public transportation and building construction, where safety standards are stringent. Similarly, bio-based and recyclable PMI alternatives are under development to meet the sustainability goals of various industries.

5. Regional Market Dynamics

Asia-Pacific is emerging as a key growth region for the PMI foam market, fueled by rapid industrialization, government investments in infrastructure, and the expansion of local aerospace and wind energy sectors. Countries like China and India are not only major producers but also significant consumers of PMI foam-based products.

Meanwhile, North America and Europe remain dominant markets due to their mature aerospace and defense industries and strong commitments to renewable energy. Strategic partnerships between raw material suppliers and end-users are expected to drive innovation and cost-efficiency in these regions.

6. Challenges and Opportunities Ahead

Despite its promising outlook, the PMI foam industry faces challenges such as high production costs, supply chain disruptions, and regulatory hurdles regarding chemical usage and waste management. However, ongoing research into alternative feedstocks and eco-friendly manufacturing methods could help mitigate these issues.

Furthermore, as additive manufacturing (3D printing) gains momentum, there is potential for PMI foam to be integrated into novel composite fabrication processes, unlocking new design possibilities and application areas.

Conclusion

Looking ahead, the future of PMI foam appears bright. Its unique combination of mechanical strength, thermal stability, and low density positions it as a preferred core material in high-tech industries. With continued innovation and broader adoption across sectors like aerospace, renewable energy, and electric mobility, the PMI foam market is set to expand significantly in the coming years.

As companies invest in R&D and sustainability initiatives, PMI foam will likely play a pivotal role in shaping the next generation of lightweight, high-performance composite materials.

PMI foam

Latest News