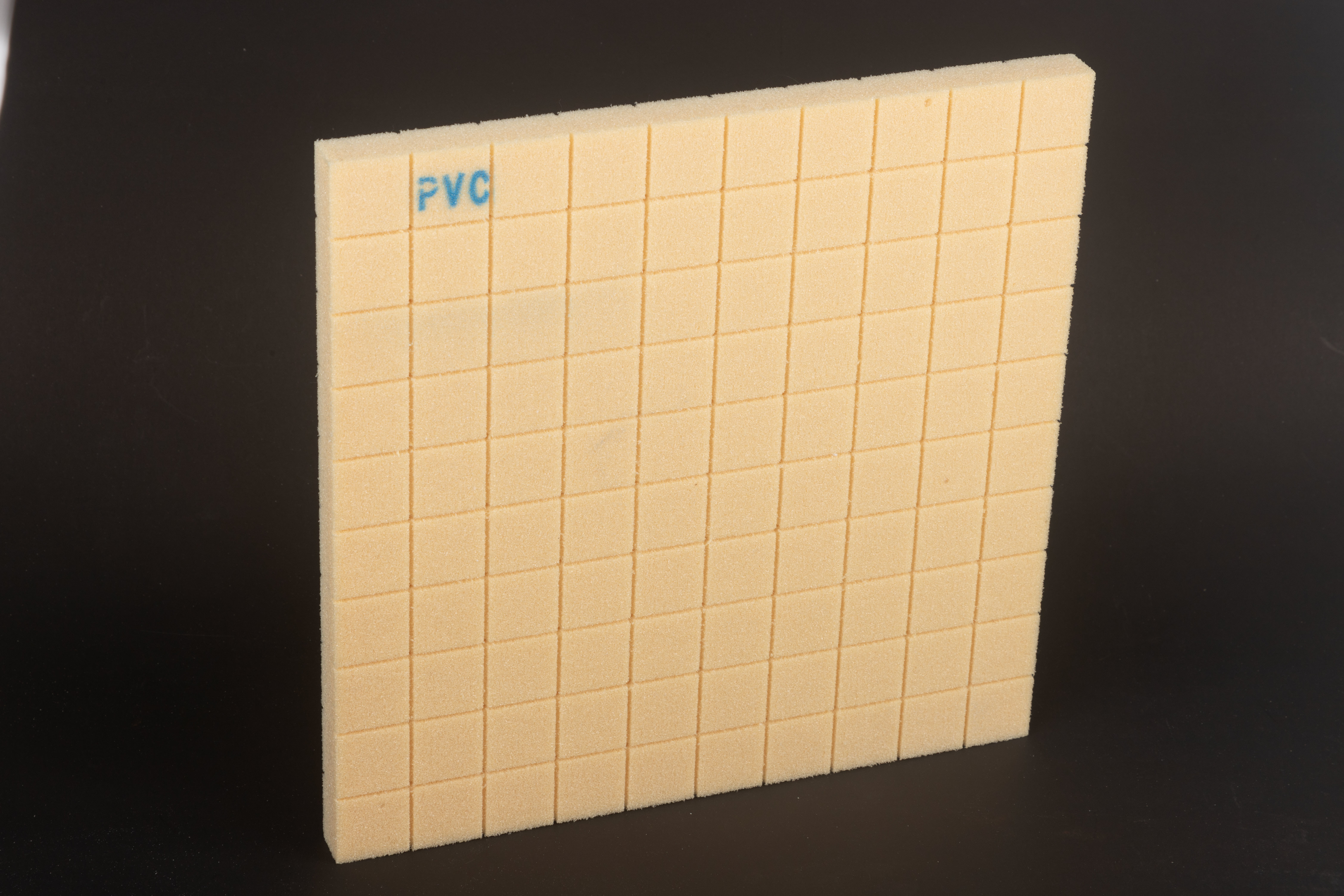

Innovations in Slow-Recovery PVC Foam for Automotive and Medical Applications

The global demand for slow-recovery PVC foam, a flexible closed-cell material renowned for its shape-retention and energy-absorption capabilities, has surged in recent years. This foam’s unique cellular structure enables it to compress under pressure and gradually revert to its original form, making it ideal for applications requiring sustained cushioning and shock absorption.

In the automotive sector, slow-recovery PVC foam is revolutionizing seating design. Traditional cushioning materials often degrade over time due to repeated compression, leading to discomfort and reduced support. In contrast, PVC foam maintains its elasticity and structural integrity even after prolonged use. Major manufacturers like Vita and Crown General now integrate this foam into premium vehicle interiors, offering enhanced comfort for drivers and passengers. Its resistance to moisture, chemicals, and temperature fluctuations further extends its durability, making it suitable for both indoor and outdoor automotive applications.

Beyond automotive use, the medical industry has embraced slow-recovery PVC foam for orthotic devices. Its ability to conform to body contours while providing consistent pressure distribution makes it invaluable for braces, splints, and prosthetic liners. Unlike rigid materials, PVC foam adapts dynamically to patient movements, reducing friction and skin irritation. A study by the Rubber Company highlighted a 30% reduction in pressure sores among patients using PVC foam-based orthotics compared to conventional alternatives.

Production advancements have also driven market growth. Manufacturers now employ Celuka (Celuka) and free-foaming techniques to optimize foam density and surface finish. For instance, AS Rubber & Plastics’ Celuka-processed PVC foam combines a hard, smooth exterior with a low-density core, balancing aesthetics and functionality. These innovations, coupled with cost-effective extrusion methods, have made slow-recovery PVC foam accessible to a broader range of industries.

As sustainability becomes a priority, manufacturers are exploring bio-based additives to reduce the foam’s environmental footprint. While challenges remain in scaling eco-friendly formulations, the material’s inherent recyclability and longevity align with global circular economy goals.

In conclusion, slow-recovery PVC foam’s versatility across automotive and medical sectors underscores its potential to redefine comfort and functionality standards. With ongoing R&D focused on performance optimization and sustainability, this material is poised to dominate high-value applications for years to come.

Slow-Recovery PVC Foam,Automotive Seating,Medical Orthotics

Latest News