PVC Foam in Action: Signage, Thermoforming, and Marine Innovation

Beyond its impressive inherent properties, the true value of Polyvinyl Chloride (PVC) foam shines through in its diverse applications. Its workability, durability, and aesthetic flexibility have made it a cornerstone material in several key sectors, notably transforming the signage industry, enabling complex thermoforming applications, and becoming a vital component in advanced marine composites.

Dominating the Signage Industry

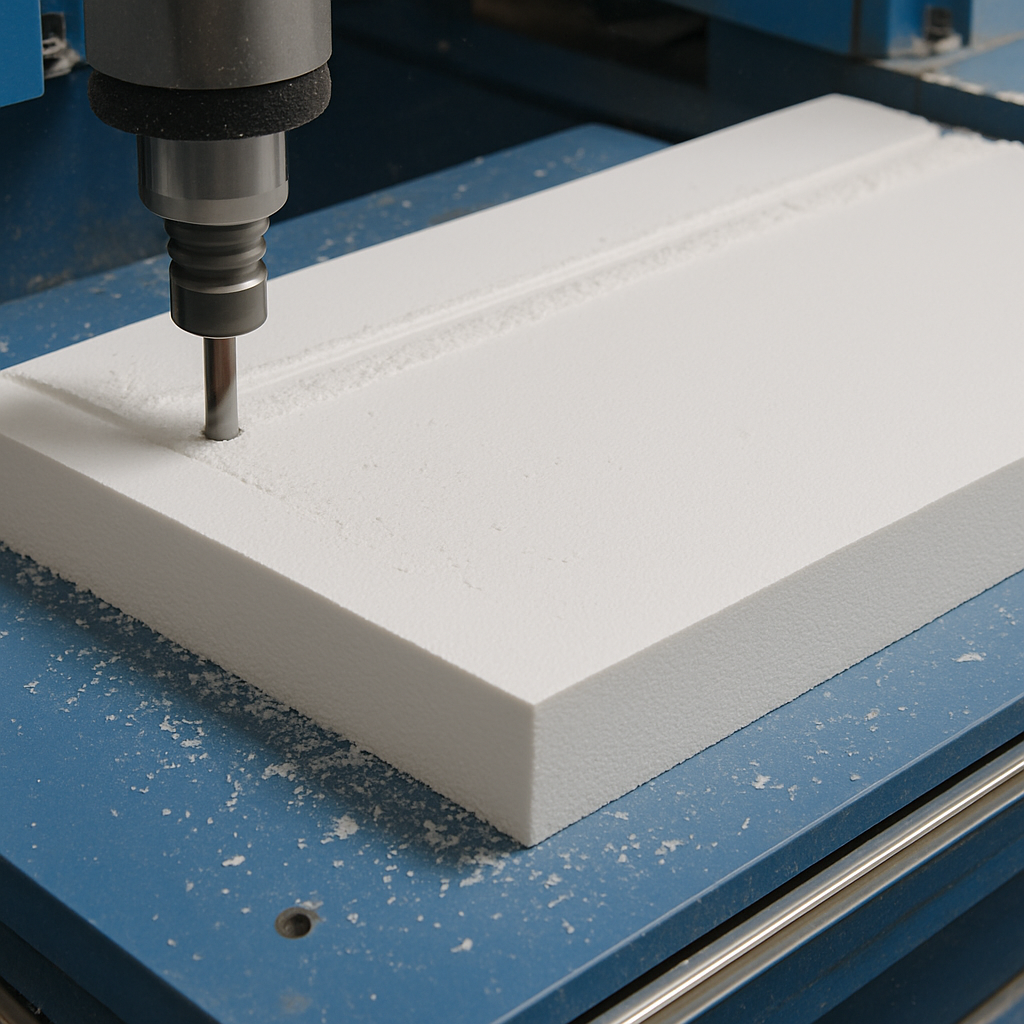

PVC foam, particularly in its rigid sheet form, has become the undisputed leader in the signage industry for numerous compelling reasons:

Superior Fabrication:It machines effortlessly with CNC routers, lasers, and saws, allowing for intricate cuts, detailed engravings, and precise lettering. Edges can be easily finished to a smooth, paint-ready surface.

Exceptional Durability:Resistant to UV radiation (when properly stabilized), moisture, chemicals, and impact, PVC foam signs withstand harsh outdoor environments far better than wood or many other foams. They resist warping, cracking, and fading.

Lightweight & Rigid:Easy to handle, transport, and install, even for large signs, while maintaining structural integrity without heavy backing.

Perfect Substrate:Provides an excellent, stable, and consistent surface for painting, digital printing (using specialized inks and primers), screen printing, vinyl application, and laminating.

Aesthetic Versatility:Available in various densities, thicknesses, colors (including white and black core), and surface textures (smooth, matte, textured), offering designers immense creative freedom. It can mimic the look of painted wood or metal but with superior performance.

From simple indoor plaques to massive outdoor billboards, dimensional letters, point-of-purchase displays, and exhibition stands, PVC foam delivers the quality and longevity demanded by professional sign makers and their clients.

Unlocking Shapes: Thermoforming Applications

A key advantage of certain grades of PVC foam is their suitability for thermoforming applications. When heated to a specific temperature range, PVC foam sheets become pliable. They can then be vacuum-formed or pressure-formed over molds to create complex three-dimensional shapes:

Complex Geometries:Enables the production of curved panels, contoured housings, trays, and enclosures that would be difficult or impossible to machine economically from solid blocks.

Lightweight Structures:Maintains the core benefit of low weight even in complex forms.

Cost-Effective Prototyping & Production:Thermoforming is generally faster and more economical for producing complex shapes in medium volumes compared to injection molding, especially for larger parts.

Applications:Widely used for vehicle interior panels (truck liners, RV components, aircraft cabin parts), medical equipment housings, kiosks, protective packaging, and architectural elements like curved cladding or column covers. The thermoformed part retains the core properties of the PVC foam, including rigidity, chemical resistance, and ease of finishing.

Strength on the Water: Marine Composites

The marine environment demands materials that resist constant assault from water, salt, UV, and mechanical stress. PVC foam has emerged as a premier core material in marine composites, specifically in Sandwich Panel Construction:

The Sandwich Principle:PVC foam sheets are laminated between two strong, rigid skins, typically fiberglass (GRP) or carbon fiber reinforced polymer (CFRP). The foam core provides separation and stabilizes the skins.

Key Contributions:The core provides exceptional stiffness and strength-to-weight ratio (critical for hull performance), buoyancy, thermal and acoustic insulation, vibration damping, and resistance to water ingress (thanks to its closed-cell structure). Its compatibility with polyester and epoxy resins used in boat building is excellent.

Performance Benefits:Boats built with PVC foam cores are lighter (leading to higher speed, better fuel efficiency, and greater payload), stiffer (better handling and reduced hull flex), quieter, and offer superior insulation. It's used in hulls, decks, bulkheads, superstructures, and even high-performance racing yachts. Its resistance to osmosis is a significant advantage over traditional materials like balsa wood.

PVC foam is far more than just a raw material; it's an enabling technology. Its transformative impact on the signage industry is undeniable, providing the perfect blend of workability, durability, and aesthetics. Its adaptability through thermoforming applications unlocks complex, lightweight shapes for transportation and beyond. Finally, its role as a high-performance core in marine composites pushes the boundaries of boat design, delivering strength, lightness, and resilience on the open water. PVC foam continues to prove its versatility as a solution-driven material across these diverse and demanding fields.

PVC foam

Latest News