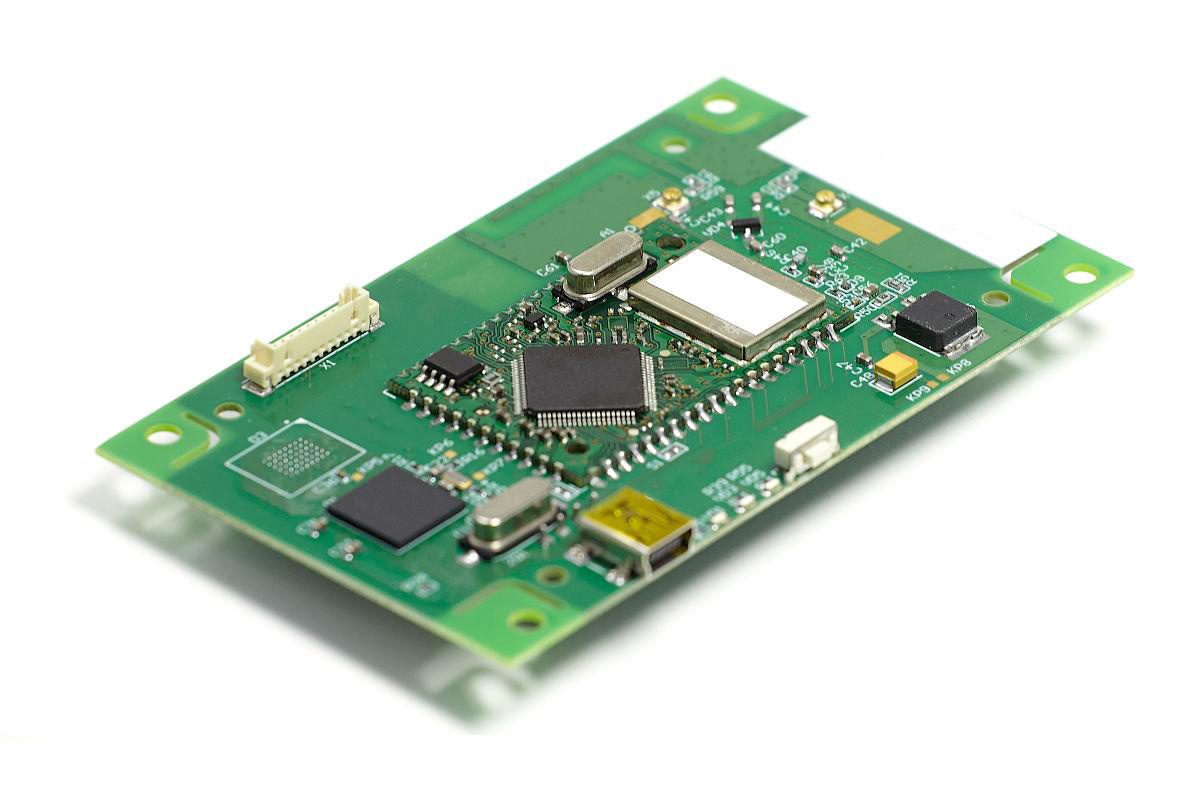

PMI Foam: A Game-Changer for High-Performance PCBs

As electronics become more complex and compact, the demands on printed circuit boards (PCBs) are greater than ever. Engineers are constantly searching for innovative materials that can improve a PCB's performance, especially in high-frequency and high-speed applications. One such material that is rapidly gaining traction is PMI (Polymethacrylimide) foam. This lightweight yet strong polymer foam is proving to be a game-changer for next-generation electronics.

What is PMI Foam?

PMI foam is a rigid, closed-cell polymer foam known for its excellent mechanical properties and high thermal stability. Originally developed for structural applications in aerospace and automotive industries, its unique combination of characteristics makes it ideal for use in advanced electronics.

Unlike traditional PCB substrates like FR-4, which can have poor performance at high frequencies, PMI foam offers a superior solution. Its key advantages include:

- Extremely Low Dielectric Constant (Dk): The Dk of a material measures its ability to store electrical energy in an electric field. A lower Dk is crucial for high-speed signals, as it reduces signal loss and distortion. PMI foam's Dk is significantly lower than that of conventional materials, allowing for faster signal propagation and improved signal integrity.

- Very Low Dielectric Loss Tangent (Df): The Df, also known as the loss tangent, indicates the amount of energy lost in a material. A lower Df means less signal attenuation. For high-frequency applications like 5G, radar, and satellite communications, a low Df is essential to maintain signal strength over long traces.

- High Thermal Stability: PMI foam can withstand high temperatures without degrading, making it compatible with standard PCB manufacturing processes like soldering and lamination.

- Lightweight and Strong: Its exceptional strength-to-weight ratio allows for the creation of lightweight yet structurally robust PCBs, which is particularly beneficial for portable and aerospace electronics.

How is PMI Foam Used in PCBs?

PMI foam is primarily used as a core material in high-frequency and millimeter-wave (mmWave) circuit boards. In these applications, it replaces a portion of the traditional, heavier dielectric material.

A common application is in mmWave antenna-on-board (AoB) designs. The foam is used as a low-Dk dielectric layer between the antenna and the ground plane. This configuration effectively reduces parasitic capacitance and improves the antenna's radiation efficiency. The result is a more compact, efficient, and higher-performing antenna module.

Another key application is in multi-layer PCBs. By selectively integrating PMI foam in areas where high-speed signals need to travel, engineers can create hybrid boards that optimize performance while managing cost. This approach allows for the creation of innovative designs like 3D-printed circuits with embedded foam cores, which are being explored for future generations of electronics.

The use of PMI foam also simplifies the design process for complex systems. By providing a stable, low-loss substrate, it reduces the need for extensive signal conditioning and allows designers to achieve higher data rates with less effort.

The Future is Lightweight and Fast

The adoption of PMI foam is a testament to the ongoing evolution of materials science in the electronics industry. As we push the boundaries of wireless communication and data processing, materials that can handle the increased demands of high frequencies are becoming indispensable. PMI foam offers a compelling solution, enabling engineers to create smaller, lighter, and faster electronic devices.

Its role in advancing technology from 5G infrastructure to autonomous vehicles and satellite communication is poised to grow, solidifying its place as a key material for the future of electronics.

PMI foam

Latest News