PMI Foam: The New Frontier in High-Fidelity Audio Diaphragms

For audiophiles and sound engineers, the quest for perfect sound is a continuous journey. At the heart of every speaker is the diaphragm, a component that converts electrical signals into sound waves. The material used for this crucial part dictates everything from a speaker's clarity and speed to its bass response. While traditional materials like paper, silk, and plastics have long dominated the industry, PMI (Polymethacrylimide) foam is emerging as a revolutionary alternative, offering distinct advantages that are changing the game for high-end audio.

Why Material Matters: The Science of Sound

A speaker diaphragm needs to move with incredible speed and precision to accurately reproduce complex audio signals. Key material properties that influence performance are:

- Stiffness-to-Weight Ratio: A stiffer diaphragm can move as a single, uniform piston without bending or deforming, which prevents sound distortion. A lighter diaphragm can accelerate and decelerate faster, improving transient response and detail. The ideal material has a high stiffness-to-weight ratio.

- Damping: This refers to a material's ability to absorb unwanted vibrations and resonances. Too little damping can lead to a "ringing" sound, while too much can make the audio sound "dull" or "lifeless."

- Speed of Sound: This property dictates how fast a signal travels through the material. A faster speed of sound allows the diaphragm to reproduce higher frequencies more accurately.

PMI Foam vs. Traditional Materials: A Head-to-Head Comparison

Let's look at how PMI foam stacks up against common diaphragm materials:

|

Material |

Pros |

Cons |

PMI Foam Advantage |

|

Paper |

Inexpensive, good damping, lightweight |

Prone to moisture damage, inconsistent stiffness |

PMI offers superior stiffness, moisture resistance, and consistency. |

|

Silk/Fabric |

Great for soft dome tweeters, excellent damping |

Not rigid enough for woofers or mid-range, limited frequency range |

PMI provides the necessary rigidity for full-range applications while maintaining excellent detail. |

|

Plastics (e.g., Polypropylene) |

Durable, well-damped, good for low frequencies |

Heavier and less stiff than PMI, can sound "slow" |

PMI's low mass and high stiffness lead to faster, more dynamic bass and clearer mids. |

|

Metals (e.g., Aluminum) |

Very stiff, lightweight |

Prone to "cone breakup" and ringing at high frequencies, poor damping |

PMI's inherent damping properties prevent the ringing and harshness often associated with metal drivers. |

The Key Advantages of PMI Foam

PMI foam stands out because it strikes a near-perfect balance of the critical properties required for a high-performance diaphragm.

1.Exceptional Stiffness-to-Weight Ratio: This is PMI foam's superpower. It is significantly stiffer than paper or plastic at a fraction of the weight, allowing it to move with lightning-fast speed and reproduce every nuance of the audio signal without distortion. The result is a sound that is incredibly detailed, dynamic, and lifelike.

2.Superior Damping Characteristics: Unlike metals that can "ring" at certain frequencies, PMI foam naturally absorbs and dissipates unwanted vibrations. This eliminates the harshness and coloration that can plague other materials, leading to a clean, pure sound across the entire frequency spectrum.

3.

The Future of Audio is Lighter and Faster

The adoption of PMI foam is a testament to the audio industry's continuous innovation. By leveraging materials science, manufacturers are no longer constrained by the limitations of traditional materials. PMI foam allows for the creation of speaker drivers that deliver a level of performance previously unattainable. As engineers continue to refine designs, we can expect to see PMI foam-based diaphragms become the new standard for premium loudspeakers, bringing us one step closer to truly perfect sound.

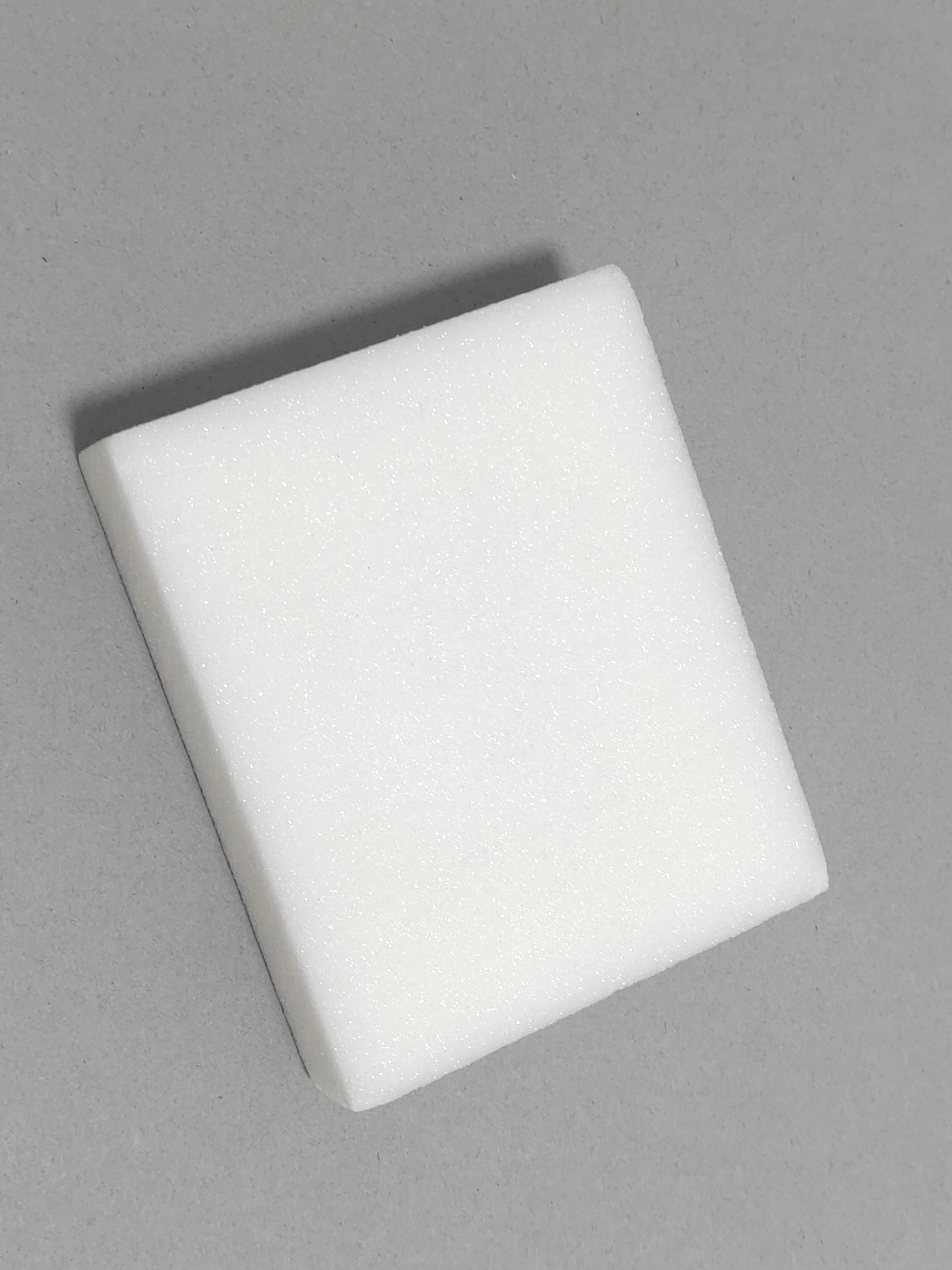

pmi foam

Latest News