Why PMI Foam is the Core Choice for High-Performance Sports Equipment

PMI Foam: The Lightweight Champion in High-Performance Sports Equipment

In the world of sports equipment, every technological advancement aims to help athletes break physical limits, enhance competitive performance, and reduce injury risk. Whether it’s rowing paddles, skis, high-performance bicycle rims, or watersports gear, the core demands remain constant: minimal weight combined with maximum strength and dynamic responsiveness.

For a long time, manufacturers relied on fiberglass, carbon fiber, and traditional foam cores (like PVC foam, Polyurethane PU foam, and PET foam) to create composites. However, these conventional core materials face limitations in high specific strength, fatigue life, and manufacturing efficiency.

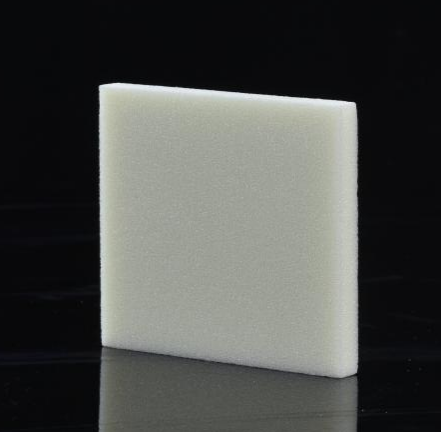

PMI Foam (Polymethacrylimide foam, commercially known by brands like ROHACELL®), as an advanced closed-cell rigid structural foam, is now widely adopted in elite-level sports equipment due to its exceptional combination of properties, becoming the core choice for high-performance composite design.

Three Key Advantages of PMI Foam Over Traditional Materials

1. Ultimate Specific Strength: The Perfect Balance of Lightweighting and Stiffness

This is the most disruptive advantage of PMI foam. Specific strength (ratio of strength to density) and specific stiffness (ratio of stiffness to density) directly determine the equipment’s performance:

- PMI Foam vs. PVC/PU Foam: At the same density, PMI foam exhibits significantly higher tensile, compressive, bending, and shear strengths than PVC, PET, or PU foams. This means manufacturers can use lower-density PMI foam to achieve greater weight savings while maintaining or even increasing structural rigidity. For instance, rowing paddles or bicycle rims using PMI foam are not only lighter but also offer higher energy transfer efficiency and instantaneous responsiveness, directly translating to superior athletic performance.

- Performance Enhancement: Higher stiffness ensures minimal deformation under load, allowing skis to maintain precise edge control, and paddles to maximize the conversion of the athlete's force into propulsion—a crucial factor in competitive advantage.

2. Superior Fatigue Resistance and Durability

High-performance sports equipment is constantly subjected to extreme cyclic loading (fatigue) and impacts.

- PMI Foam's Unique Structure: The unique cross-linked molecular structure of PMI foam provides excellent creep resistance (resistance to deformation under sustained load) and fatigue resistance. In contrast, traditional materials like PU foam are prone to deformation or loss of strength under long-term and dynamic loading, which can ultimately lead to equipment failure.

- Application Value: In surfboards, paddleboards, or windsurf boards, PMI foam ensures the equipment does not delaminate or structurally degrade after years of exposure to water and impact, greatly extending the product’s service life.

3. High Temperature Stability and Efficient Manufacturing

Traditional foam cores (like PVC) can generally only withstand lower curing temperatures, limiting manufacturers' choices of high-performance resins and efficient manufacturing processes.

- High-Temperature Compatibility: PMI foam has a high heat distortion temperature of 180∘C or higher, allowing it to be co-cured at high temperatures with high-performance matrix resins like epoxy and cyanate ester. This ensures the highest quality and strength of the composite interface bond.

- Manufacturing Efficiency: High-temperature stability enables manufacturers to use faster, more efficient prepreg curing cycles or RTM (Resin Transfer Molding) processes, significantly reducing production time and increasing output. PMI foam's fine closed-cell structure also minimizes resin absorption, ensuring the final part's weight is precisely controlled.

Conclusion: Beyond Lightweighting, Defining Performance

The application of PMI foam in sports equipment is more than simple weight reduction; it provides a comprehensive solution for structural enhancement, optimized responsiveness, and long-lasting durability. For sports brands pursuing a millisecond advantage and top quality, PMI foam has become the key technology to achieve a performance leap, differentiating standard materials from competition-grade gear.

Polymethacrylimide foam,PMI foam

Latest News